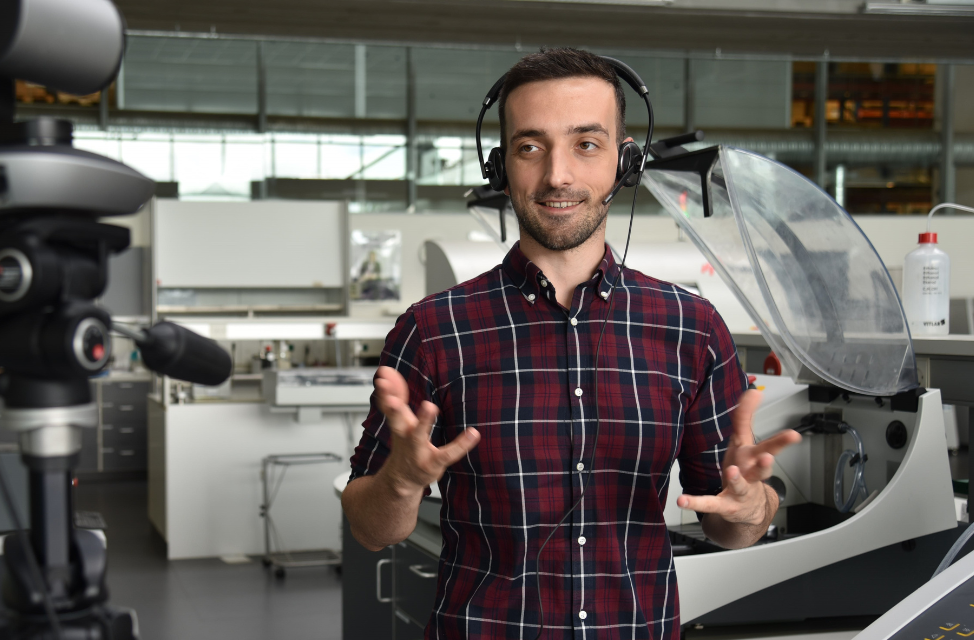

HERZLICH WILLKOMMEN BEI DER STRUERS ACADEMY

Wir sind fest von der Bedeutung des Austausches von Wissen überzeugt. Was Sie heute lernen, sollte morgen in Ihrem Labor angewendet werden. Das gilt von der Präparation bis zur Werkstoffuntersuchung und der Wartung der Geräte.

Die Struers Academy bietet metallographische Schulungen und Webinare an, die auf Ihre Anforderungen abgestimmt sind. Sie können beispielsweise an einer individuellen Schulung teilnehmen, einen auf Ihre Anforderungen zugeschnittenen Kurs absolvieren oder an einem unserer beliebten Online-Webinare teilnehmen, um Ihr Wissen über die materialographische Präparation zu erweitern.

Zum Schulungs- und Webinarkalender