Grabación de seminario web

Microstructure of Thermal Spray Coatings: Sample Preparation and Examination

Please join us as Struers discusses Microstructure of Thermal Spray Coatings: Sample Preparation and Examination.

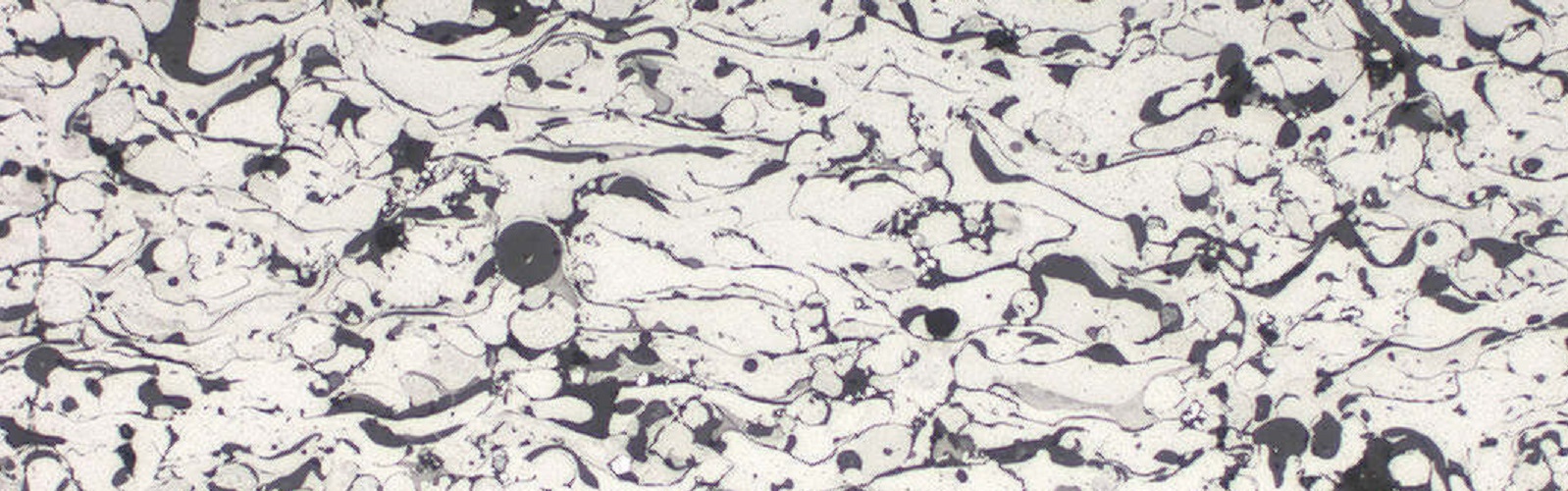

Thermal spray coatings are used in various engineering applications to provide resistance to heat (thermal barrier), wear, cavitation, abrasion, etc. Many techniques such as arc spray, high-velocity oxy fuel (HVOF), and plasma spray are available for the application of thermal spray coatings and they all basically entail the projection of molten or semi-molten droplets onto a prepared substrate where they harden and form a continuous protective coating.No matter what technique is used to apply a thermal spray coating, materialographic preparation and examination are necessary for quality control to assess coating thickness, amount and distribution of porosity, the presence of oxides and un-melted particles, as well as adhesion integrity. Incorrect grinding and polishing procedures can influence porosity results; it is therefore imperative that these steps are done in a systematic and repeatable manner.

Key Takeaways:

- Difficulties during sample prep and how to overcome them

- Preparation steps: best practices for cutting, mounting, grinding and polishing

- Methods & examples